In the vast realm of packaging materials, one unsung hero quietly goes about its job – PET Shrink Film. This unassuming material has been a game-changer in various industries, offering a versatile and efficient solution for packaging needs. In this blog post, we will delve into the world of PET Shrink Film, exploring its characteristics, applications, and the myriad ways it acts as an unseen protector for products across different sectors.

I. Understanding PET Shrink Film:

A. Composition and Properties:

Polyethylene Terephthalate, commonly known as PET, forms the base of PET Shrink Film. This material, renowned for its clarity, strength, and versatility, undergoes a specialized manufacturing process to create a shrinkable film. The film is characterized by its ability to shrink and conform tightly to the shape of the product when heat is applied, creating a secure and protective layer.

B. Transparency and Aesthetics:

One of the standout features of PET Shrink Film is its transparency. This quality not only allows for the product inside to be visible, enhancing its appeal on the retail shelf, but also provides an excellent surface for printing, branding, and product information. The aesthetics of PET Shrink Film contribute to an overall premium presentation of the packaged product.

II. The Versatility of PET Shrink Film:

A. Beverage Industry:

PET Shrink Film has become a staple in the packaging of beverages, particularly for bottled water, soft drinks, and other bottled beverages. The film offers a tamper-evident seal, ensuring the integrity of the product, while also providing a visually appealing and informative packaging solution.

B. Food Packaging:

In the food industry, where freshness and visual appeal are paramount, PET Shrink Film plays a crucial role. Whether it’s wrapping fresh produce, meats, or bakery items, the film helps maintain product quality, extends shelf life, and prevents contamination. Additionally, the clear and printable surface of the film allows for vibrant branding and product information.

C. Consumer Goods:

Beyond food and beverages, PET Shrink Film finds extensive use in packaging various consumer goods. From electronics to cosmetics, the film offers a protective layer that not only safeguards the product during transit but also enhances its visual appeal on the retail shelf. The versatility of PET Shrink Film makes it suitable for a wide range of products in the consumer goods sector.

III. Advantages of PET Shrink Film:

A. Tamper-Evident Packaging:

One of the primary advantages of PET Shrink Film is its ability to provide tamper-evident packaging. When heat is applied, the film shrinks and conforms tightly to the product, creating a seal that is immediately visible if tampered with. This feature instills confidence in consumers regarding the safety and authenticity of the packaged goods.

B. Protection Against Contaminants:

PET Shrink Film acts as a barrier against external contaminants, including dust, dirt, and moisture. This protective layer is particularly crucial in industries where maintaining product quality and hygiene is of utmost importance, such as food and pharmaceuticals.

C. Enhanced Branding Opportunities:

The transparent and printable surface of PET Shrink Film opens up opportunities for vibrant branding and product information. Manufacturers can leverage this feature to communicate essential details about the product, brand messaging, and regulatory information in a visually appealing manner.

IV. Sustainability Aspects of PET Shrink Film:

A. Recyclability:

Sustainability is a growing concern in packaging, and PET Shrink Film aligns with eco-friendly practices. The material is recyclable, contributing to the reduction of plastic waste. The recyclability of PET Shrink Film positions it as a responsible choice for companies aiming to minimize their environmental impact.

B. Lightweight Nature:

Compared to traditional packaging materials, PET Shrink Film is lightweight. This characteristic not only reduces transportation costs but also lessens the overall environmental footprint associated with the packaging process.

V. Applications Beyond Packaging:

While the primary use of PET Shrink Film is in packaging, its versatility extends beyond this realm. The film is employed in various industries for purposes such as bundling, labeling, and even artistic endeavors. Exploring these unconventional applications provides insights into the diverse utility of PET Shrink Film.

VI. Challenges and Solutions:

A. Heat Application:

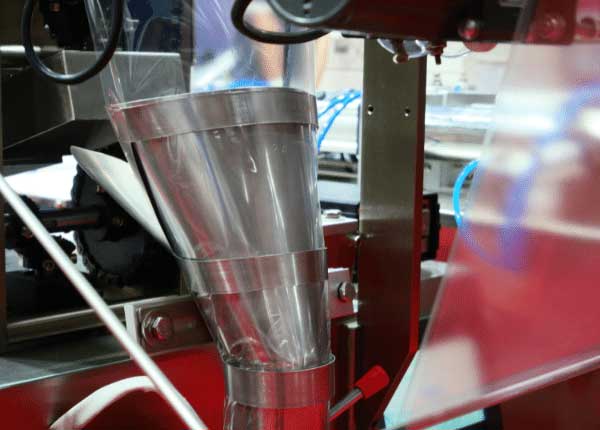

The shrink ability of PET Shrink Film is reliant on heat application. While this is a fundamental aspect of its functionality, it can pose challenges in certain scenarios. Innovations in heat application technologies and equipment have addressed these challenges, ensuring a seamless and efficient packaging process.

B. Compatibility with Different Materials:

PET Shrink Film may not be universally compatible with all materials, especially those that are sensitive to heat. Understanding the compatibility of the film with various products and materials is essential in overcoming potential challenges in the packaging process.

VII. Conclusion:

In conclusion, PET Shrink Film stands as an unseen protector in the world of packaging. Its versatility, transparency, and protective properties make it an invaluable asset across various industries. As we navigate the evolving landscape of packaging materials, PET Shrink Film continues to prove its worth as a reliable, efficient, and environmentally responsible solution. Whether it’s safeguarding the freshness of food, ensuring the authenticity of beverages, or enhancing the visual appeal of consumer goods, PET Shrink Film quietly but effectively plays its role as the unseen hero in the packaging world.